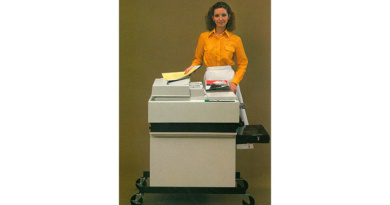

Xerox 1055

Last modified: Dec 13, 2024 @ 1:50 pm

March 1984: Xerox launches their marathon model 1055.

The following text is taken from the 1055 product information: The Xerox 1055 handles very large copying. It takes originals up to A2 size, and makes copies up to B3 size (40% bigger than A3). It speeds through A4 jobs at up to 50 copies per minute, and fast, multiple A3 size-for-size copies at 27 per minute. While the semi-automatic document handler lets you feed originals up to three times faster than manual copying. Quite a productivity benefit.

The 1055 enlarges, as well as reduces, makes double-sided copies, sorts and collates. It even folds A3 copies to A4 size. This means you can incorporate big charts, drawings or plans into A4 reports, folded and inserted automatically, into collated sets of up to 50 sheets each.

| SPECIFICATIONS | |

|---|---|

| Copy speed (per minute) | 50 (A4) 27 (A3) |

| Paper tray | n/a |

| Output tray capacity | n/a |

| Finisher/sorter | 15-bins sorter |

| Staple function |  |

| Reduction/zoom |  |

| Document handler | Semi automatic document handler |

| Dimension and weight | |

| Depth | 82 (cm) / 32 (inches) |

| Width | 104 (cm) / 41 (inches) |

| Height | 94 (cm) / 37 (inches) |

| Weight | 331 (K grams) / 730 (Lbs) |

| Floor space requirements | 2 x 2 (meters) / 6.6 x 6.6 (feet) |

Do you have any more information about this model, or have brochures / pictures? Please leave a reply in the form below, or send an email to xeroxnostalgia@outlook.com

The FBI in DC had eight 1055’s that had a two up kit on document handler a slitter at the exit than copied finger print cards 24/7/364 if I remember correctly you changed the original developer at 20k and a while later the new developer was changed at 50k my memory may be off on the actual interval but I was constantly changing developer and rebuilding fuses which would leak oil everywhere if not rebuilt exactly right. They ran those machines too death. I transferred to Richmond Virginia at the end of 85 and rarely saw a1055 after that. I… Read more »

Oh, I started with Xerox in 1977 my employee number was N66K

The 1055 was a specialty product. The was a Fuji machine with a Xerox name.

I used to like the funny noises those little motors made when you selected a reduction mode on the 1055s.

The 1040 was introduced in 1985 right after the launch of the 1048.

I serviced the Xerox 1040. The Xerography of this machine was touchy. The exposure, electrostatic and solid density had to be set up just right otherwise paper jams ensued. The ADC sensor served 3 purposes. It registered the paper coming out of the tray. It was used for jam detection and solid density control. This was improved on the 1050 model which used a mechanical preregistration sensor similar to the 1045 model. This machine also used selenium drum with an aluminum substrate.

I serviced this machine. When they first came out, at the time, this machine was something new. This is comparing 660 II and 3100f machines. First time I saw a computer 8086 processer chip on the mother board. The copy machine still had the selenium Drum; made a decent copy. It had a stripper finger under the drum and left a light area deletion when customers ran photo dark copies. In my opinion, I didn’t mind servicing this model.

In the UK we modified the position of the stripper finger from center to the edge of the drum to remove the white mark. However it was not very successful in stripping the paper and a lot of machines were put back in the center. The other problem was the sorter seemed to be designed for B size Japanese paper, causing jams. I did like working on the product, the Japanese design was engineer friendly, if I remember correctly.