Xerox Standard Equipment

Last modified: Dec 11, 2024 @ 12:36 pm

In 1950 Haloid announced the Xerox Standard Equipment. It consists of the Xerox camera No. 4, Processord "D" and a Heat Fuser. When Rank Xerox was established in 1956, they named this equipment Rank Xerox Standard 1385. Another name was also used - The Xerox Master maker 1385.

The 1385 consists of a Processor, Camera, Heat Fuser, Vapour Fuser. The 1385 uses the seven stages of the Xerographic process. Each stage of the process is a seperate manual one. It would take around five minutes to complete the process per sheet of paper.

The Model 1385 was among the first commercially available xerography machines, later known as photocopiers.

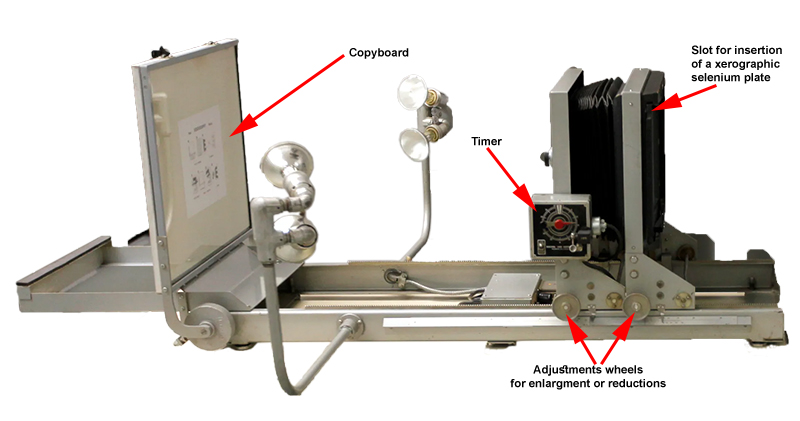

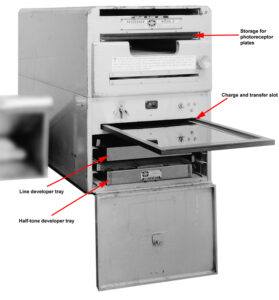

Below is images which describes the different components, of the Xerox Standard Equipment / Rank Xerox Standard 1385.

This is the Camera No. 4 VR, which means it's a Variable Ratio camera. The original to be copied, is placed on the copyboard. Use the adjustments wheels if you want to enlarge, or reduce the copied image. Insert a charged xerographic plate into the slot, in back of the camera. Finaly, set the timer for preferred amount of exposure, and start the exposure.

This is the Processor D unit. This was used to charge the xerographic plate before an image was exposed with the Camera No. 4. After the plate was charged, the operater inserted the plate into the Camera No. 4. When the image was exposed with the Camera, the operater took the plate out of the camera.

The operator placed the plate in toner tray in the Processor D, and toner was cascaded over the xerographic plate. Then the operator took the plate out, and laid a peace of paper onto the plate. The plate was again inserted into the charge and transfer slot in the Processord D, and was then charged in order for the image to be transferred to the paper.

Here is the heat fuser. The last step of operations, was that the operator needed to fuse the toner onto the paper. It was then up to the operator's judgement to leave it in the Fuser just long enough to fix the image, without scorching the paper.

Thanks to Stuart Yearsley for providing the information.

I’m looking for anyone with information on whether it’s possible to replace the selenium plates used in 1950s Xerox/Haloid flat-plate equipment. Modern printers use OPC drums or belts — could an OPC belt be used in a Xerox/Haloid flat-plate system?

Any information would be greatly appreciated.

Yes, with some caveats. Modern photoreceptors are much more light sensitive than the selenium plates, so it is important to keep the OPC away from daylight or fluorescent room lights as much as possible. Selenium can be charged either positive or negative; OPCs can only be charged negative. Depending on the particular OPC, charge can leak, so time from charge sensitization through exposure to development should be minimized. Much trial-and-error work is likely to be required.

Thanks for the info.