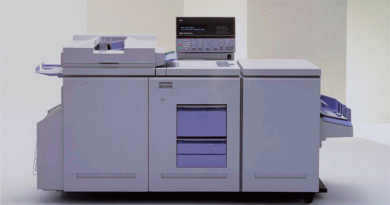

Xerox 2300

Last modified: Dec 13, 2024 @ 1:15 pm

May 1979 Xerox announced the 2300 model to the market. The compact Xerox 2300 was designed for the small office or small business that didn't do a lot of copying. The first copy appeared after 6 seconds, the rest at a rate of 10 per minute.

Accepted input originals up to 8 1/2" x 14" legal size, including photograps, paste-ups and bound volumes

Quantity selector could be dialed from 1 to 15; automatically returns to 1 after the job.

The paper path inside the copier was quite simple. When the paper left the paper tray, a "gripper bar" with two clips opened and grabbed the paper and transported it under the drum, and through the fuser. The fuser unit was a heat roller and pressure roller, and the paper passed between the two rollers in order for the toner to melt into the paper.

The control panel consisted of the ordinary green Start print/copy button, and a wheel with quantity selector. There was a display at the top/back end of the machine, where it showed symbols of ready and paper jam.

| SPECIFICATIONS | |

|---|---|

| Copy speed (per minute) | 10. First copy after 6.5 seconds. |

| Paper tray | 200 sheets |

| Output tray capacity | n/a |

| Finisher/sorter |  |

| Staple function |  |

| Reduction/zoom |  |

| Document handler |  |

| Dimension and weight | |

| Depth | 55 (cm) / 21.6 (inches) |

| Width | 80 (cm) / 31.4 (inches) |

| Height | 33 (cm) / 13 (inches) |

| Weight | 71 (K grams) / 156 (Lbs) |

| Floor space requirements | 2 x 2 (meters) / 6.6 x 6.6 (feet) |

Do you have any more information about this model, or have brochures / pictures, please leave a reply in the form below, or send an email to xeroxnostalgia@outlook.com

To whom it may concern, disregard any and all negative comments posted about the XEROX 2300. This machine was a workhorse and was groundbreaking. Before we got this machine we used to have to go to the library and get copies each for ten cents feeding the library photocopier, what a hassle, then I got this machine and it changed everything. This thing ran and ran and ran sometimes for 18 hours at a time, you just had to keep putting in the paper cartridge and keep it loaded up with what it needed to keep going no problem. This… Read more »

I worked in the engineering test group in Webster, NY, and worked on these for a couple years off and on. The 2300 was the first product I am aware of that was designed by Fuji Xerox and marketed in North America by Xerox. We didn’t have a good track record in the lower end, and they wanted to keep development costs low. We had the same problems in testing, they needed regular maintenance to keep them running. Decisions were made above my level, but apparently the projected service costs were acceptable. The subsequent FX products were much improved, the… Read more »

I used to own one, back in 1987, and I used it for 3 years. namely my copy tank!

The Xerox 2300/50 was my biggest nightmare, specially when the idler gears needed to be replaced, the schools had them and they run the crap out of them, I was the specialist for that machine, and adjusting the paper feed was a pain, it got to the point that just by listening to the machine run I could tell why it was jamming, it collected so much developer and fuser oil on the bottom, that the gripper bar would contaminate the drum and everything else. Those were the days…

LoL !! You guys are funny. These are the same opinions we had on this product. This machine had something like, 660 gripper bars that collected the leaking oil which the gripper bar touch the drum and;;; wow what a mess this was. The machine had to have a black rubber drive roller installed to replace the clear roller for reliable paper feeding. Well it worked a little better… One time this constructions place in Corcoran California, they turned off the air conditioning on the weekend; they had a service call for grinding noise. Well, it was so hot in… Read more »

I was the National Tech Specialist on this dog of a product in Australia. We had, like everyone else in the world, problems with the fuser roller failing. Machines that were never turned off had fuser rollers that lasted significantly longer than those where the customer turned them off each night. We identified that when the machine was turned on the temperature sensor, mounted on the rubber surface of the fuser roller, was slow to respond and meaning that the heat rod stayed on too long and caused the roller temperature to spike. This temperature spike was above the temperature… Read more »

I had to laugh when I saw the picture of the 2300 on the front of the bicycle. This copier used fuser oil that leaked all over no matter what you did. The final official “fix” for the oil leaking issue was to install an absorbent pad (that needed to be replaced periodically) to soak up the oil. By far my least favorite machine, it took longer to service than any of the larger copiers. We called them Flat Bottomed Boats, they would have made a better anchor than a copier.

CORRECTION: When the paper left the paper tray, a “gripper bar” with two clips opened and grabbed the paper and transported it under the drum, and through the fuser. The fuser unit was a heat roller, and pressure roller and the paper passed between the two rollers in order for the toner to melt into the paper. The heat roller had a light coating of silicon oil applied with a felt pad. The 2300 was a new machine with old design thoughts. They took the worst features from older models and incorporated it into their first metric design. The gripper… Read more »

Thanks for your correction. I will adjust the text of this article on the 2300 and 2350.

Don, within a few years of the time that this particular copier happened to be released, Xerox went from 80% market share down to 20 – 30%. Xerox was smoked by better japanese-made machines. They never came back, market share-wise.

Hi Jim…I was servicing this machine around 1984 in midtown Manhattan (midtown east).

Are you from Staten ,Jim?

Lots of fond memories .

These were the result of a joint effort with Fuji Xerox, but were unreliable, featureless, and dirty. The release of this copier and the related 2350 marked the beginning of Xerox product decline, especially in the small-office space. Around this time Xerox gained a reputation, especially in the service force, of producing abject junk. The company never saw the old halcyon days again.