Xerox 1045

Last modified: Dec 13, 2024 @ 1:50 pm

March 1983: Xerox announces the third copier in the 10-series, the Xerox 1045.

Designed in the UK, and manufactured in Venray.

Xerox 1045 had the ability to produce A3 * copies of 1 to 1, and it had 2 reductions of 71% and 62%.

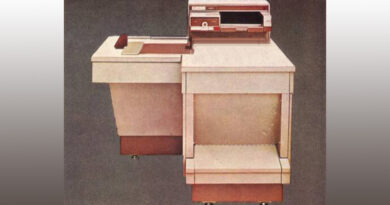

The 1045 could be delivered in four different configurations. In the image section below, you can see the different models.

The 10 series represented a new generation of copiers. This became the most successful line of copiers in Xerox history and served to restore the company's finances and morale. The flagship Xerox 1075 became the first American-made product to win Japan's Grand Prize for Good Design. Altogether, 14 models were introduced between 1982 and 1986, six of which were still sold in 1990.

| SPECIFICATIONS | |

|---|---|

| Copy speed (per minute) | 40 |

| Paper tray | Tray 1: 550 Tray 2: 220 |

| Output tray capacity | n/a |

| Finisher/sorter | Optional 15-bins sorter |

| Staple function | Optional stapler |

| Reduction/zoom | 2 pre-set reduction (71%, 62%) |

| Document handler | Semi or fully automatic document handler |

| Dimension and weight | |

| Depth | 71 (cm) / 28 (inches) |

| Width | 71 (cm) / 28 (inches) |

| Height | 94 (cm) / 37 (inches) |

| Weight | 149 (K grams) / 329 (Lbs) |

| Floor space requirements | 2 x 2 (meters) / 8 x 7 (feet) |

Do you have any more information about this model, or have brochures / pictures? Please leave a reply in the form below, or send an email to xeroxnostalgia@outlook.com

These machines used a selenium drum and had 14″ lead edge feed which you just don’t see anymore. I started on them in ’86 after working in the Oak Brook CRC on 9400’s for 7 years, what a step down lol. I rarely got over 35k between service calls cuz the waste toner backed up quickly. Still a nice simple machine for what it was.

I was an underpaid PSR working on these and 1048’s. I made one run almost a million copies between service calls, I quit Xerox for more money at Ricoh and they raised all the PSR’s up to CSR pay 9 months later.

that’s total BS the life of the drum wasn’t even that long never mind the rest of the components – plus the xerographic cleaning system would have backed up so badly- hey idiot also belts would have starched so much there would be no drive

Yep, no one could believe it. It was in bad shape when it was finally serviced. But I wasn’t lying. I tuned them lean.

I too had a territory of 1045 and 1048’s. While its true that the higher producing, large job machines, running almost non-stop ran better and longer between calls than the one at a time machines, its difficult to believe the 1045 running more than 200k without the sump backing up, or the fuser running out of lube. I eventually was sent to Leesburg to train on the Docutech, which did produce print counts near and into the million click range per call.

Started my Xerox career as a PST working on the 1045 in 1985. I remember having to disassemble the top end of all the new machines being pre-installed because the Oilite bearings dried out and squealed when the optics mirrors ran. Straight from the factory in England. I’ll never forget that.

lol i remember that we were given a special tool to press the bearing into the framing the bearing had had to be pressed perfectly straight

Oh and as for the speed, it ran 35 cpm if equipped with the platen cover and the optional Semi Automatic Document Feeder (SADF) and 40 cpm if equipped with the optional Recirculating Document Handler or RDH as it was known.

This was the first of its kind copier. I was one of the first trained on this product. It had lots of flaws when it was introduced. Once the flaws were remedied it ran like a marathon champ. This put Xerox on top of everyone that made copiers.

1045 code name Alpine was indeed a drum machine.

i was the covers industrial design engineer, along with the covers mechanical engineers, responsible for getting the production machine to look like the model and stylist illustrations. I also engineered the control panel for this machine, the 1050, the 8300

“True” 10 series in that it used the same photoreceptor belt technology as the 1075. Code name Hannibal. My two trips to Welwyn Garden City (I was a xerographic technologist based in Webster) involved consulting on this machine.

Sorry, but I have to correct you. The 1045 used a drum and the 1075 used a photoreceptor belt. The code name Hannibal belongs to the 5046. I started as a service engineer with the 1045 in 1986 and also participated on the first training for 5046.

That is correct,drum in a 1045. Part # 1R111. Hands turned a funny color from polishing them lol. First machine I was trained on back in ’87.

That was the arsenic. You were suppose to use gloves or hold it by a fist in the inside.

as I recall pumice kits came in black bag and included gloves

And polish wet unless you really wanted the ingest the dust.