Xerox 3600

Created: May 26, 2015 8:07 pm by Admin

Modified: July 4, 2024 12:05 pm by Admin

Modified: July 4, 2024 12:05 pm by Admin

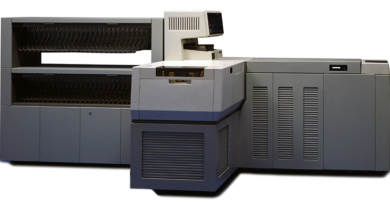

This duplicator came on the market in May 1968. Like the Xerox 2400, the Xerox 3600 has it's model number by how many copies it could produce within one hour. The Xerox 3600 could also be supplied with a sorter, as shown in the picture.

| IMAGES |

Toner and drums were tested to ensure manufacturing quality, in the test facility at Welwyn Garden City. In this photo you can see 3600, 4000, 7000 and 660 copiers.

Toner and drums were tested to ensure manufacturing quality, in the test facility at Welwyn Garden City. In this photo you can see 3600, 4000, 7000 and 660 copiers.

| SPECIFICATIONS | |

|---|---|

| Copy speed (per minute) | 60 |

| Paper tray | 2000 sheets |

| Output tray capacity | n/a |

| Finisher/sorter | 20 bins sorter in the standard version of 3600. Three further 10-bins modules can be added. |

| Staple function |  |

| Reduction/zoom |  |

| Document handler |  |

| Dimension and weight | |

| Depth | 79 (cm) / 31 (inches) |

| Width | 165 (cm) / 65 (inches) |

| Height | 127 (cm) / 50 (inches) |

| Weight | 522 (K grams) / 1151 (Lbs) |

| Floor space requirements | Stationary: 3 x 2 (meters) / 10 x 7 (feet) Movable: 3 x 2 (meters) / 9 x 7 (feet) |

Do you have any more information about this model, or have brochures / pictures? Please leave a reply in the form below, or send an email to xeroxnostalgia@outlook.com

I had worked 3600 half a year in Stockholm city, when a I a cuple of days before Christmas come to a cutomer. We ! YOU ! have a problem the manager on the site told me. My girls have rewroten all the pricelists for our company ,to be copied and sent out to all our customers all over Sweden. They have worked day and nights for weeks. And this is what the copy look likes. He showed me a copy, tha was covered with fly spots. The girl had used hard pencils. I spent a real number of hours… Read more »

I loved selling the 3600 in Manchester from 1968-1971 and selling it to major account companies enabled them to upgrade from the slower copiers and get rid of their messy stencil duplicators. Sales staff worked hard and played hard-much of which cannot be reported! The Dive Bar was the 5-30pm winding down bar-but that was just the start. Happy memories.

They were a very heavy machine and there is a story that one of our London sales guys was asked by a concerned customer if it would be safe to install a 3600 on the office wooden floor as this was directly over a basement.

The salesman told him “Don’t worry sir, the 3600 will also operate quite happily in the basement”

3600’s were a dirty, messy thing. Although they could run for years and often did. We could keep them going long past their planned life.

Remember split rubber on the fuser pressure roll? How about the times a sheet of paper got stuck in the brush housing? Engineers were known as “Hired J-cloths”.

Fault finding on all those relays was interesting. Easier when the FIMS sheets were available.

I may be wrong, but I thought they were called “FIPS” for Fault Isolation Procedure Sheet”. I was a Westminster 3600 7000 engineer from 1973 till retirement in 1995

I could be wrong too but I think it was Functionally Identified Maintenance System. It was a long time ago. My DSMs were Dick Stephens, Charlie Ball and Dick Burzynski based at Goswell Road for a while. Do you remember anyone from there?

The only name I recognise from those three is Charlie Ball, I seem to recall him being a stocky chap of average height, but again I could be wrong. My memory not being what it was, I can’t recall any of my DSM names at the moment, I’ll see if I remember some later and come back with them. The branch manager when I joined in 73 was Terry Tibbles at Great Portland Street (GPS). For the first few years I worked out of the Victoria Street facility point. The majority of my work was in the Whitehall ministries. Latterly… Read more »

Yes you’re right. A good description of Charlie. I didn’t know anyone from GPS unfortunately. The nearest I got to there was when attending some training courses at Tottenham Court Road.

From 1980 I was based at the Cambridge office and my “patch” was Essex. Interesting that you started in 1973. That was the same year as me when I was age 23. Perhaps we have engineer numbers not too far apart. Mine was 1760.

By Tottenham Court Road I think you mean the place in the road parallel to it, I forget the name, or maybe Albion House at the end of the road. My engineer number was 2099 and I was aged 29, your engineer number suggests your induction at Pagnell may have been at the beginning of 1973 and mine later in the year. My background was a bit unusual as after leaving school I trained as a motor mechanic, but was an electronics hobbyist. I then joined British Railways in 1963 as a trainee engine driver. I qualified in 1967 and… Read more »

Did anyone else work on the early Xerox Copiers and Duplicators that had been converted to Laser printers using helium neon lasers?

Does anyone have info on the 3600-III?

I worked on several of them in the late 70’s at the Washington CRC but never saw one in the field.

I remember it had a built in fire extinguisher.

Jerry Glenn a tech rep in Beaumont Texas suggested I replace a 3600 in Ideco, a company that manufactured drilling rigs, with the new 36003 hoping that it would copy the NCR third set page of an invoice that was impossible to copy…. he was right it did copy it…. being the salesman for the account that entered the order for the 36003 Xerox gave me a new Polaroid camera. No I never let Jerry use the Polaroid camera but I did take him his wife to New Orleans..

Herbert Taylor. Ph 512-825-4151

Hi Guys First thing, best regards from German Xerox Engineers I repaired all kind of stuff in the field and at the refurb beginning with the 3600/7000. I only heard about explosions from colleagues but never seen them or had them! Man that’s a long time ago, does somebody still knows how to adjust the intake arms with the two line tool? 🙂 So i try to list the Xerox Products that i repaired in the field till yet. 3600/7000 1075 1090 1005 1045 8200 8300 9200 9400 9500 9600 5090 DocuTech / DocuTech 155/180 HLC 41xx D Series Nuvera… Read more »

I seem to recall working on the development of the “AOD” for the 3600, when at SIRX. I could be wrong – it’s a while ago (1976). I also worked on the 3100 with a sorter (Model?) and a 5400 I believe it was, while in test at Mitcheldean

I used to work on the 2400, 3600, 7000 in London and then home counties during the 70s. I remember the training at Newport Pagnell well. Driving from Oxford to De ham to pick up drums, fuser oil, and PM kits. Snubbers on the paper feeder were always getting bent. Very inefficient with the brush removal of waste toner. But great days!

I have just found this site for the first time and was puzzled to discover no less that two contributors giving the same totally inaccurate explanation for the hollowing out of large solid areas on copies made by 3600 7000 etc. copiers. This effect had absolutely nothing to do with the fuser and absolutely everything to do with cascade development. One contributor even mentioned the image on the drum or copy being visibly solid throughout if you crash stopped the machine. Well this is simply not the case, crash stop the machine and both drum and unfused copy will display… Read more »

I also worked on the 3600 / 7000 range of copiers both in the field and at the refurb centre in Uxbridge. It wasn’t until I worked on the 9200 that I realised the reason the image wasn’t solid. I’m pretty sure I can remember the image was more solid ‘on the drum’ and the reason for the poor solid quality on paper was caused by the weak transfer process. This is borne out by the waste process removing the unused toner from the drum to the filter bag in huge quantities. Had the 3600 benefitted from a bias transfer… Read more »

And, the very temperamental follow up – the 3600 III. Now there was a real beauty.

3600lll, not to be confused with the 3600! The earliest models were a service nightmare. More than once I saw the other 3600l lll tech headed to the one I had just left as I was going to the one He had just left. Later there was a 2 day+ retrofit to address many of those earlier problems. The very earliest models had 13” paper feeders, although years earlier the plain paper copier market had moved to expecting 14”. A 3600 lll paper fire was well beyond any other copier paper fire in the the history of xerography. Potentially worse… Read more »

I actually had a 3600 III in my territory but I was never actually trained on it. I fortunately had worked on them in a refurb center during the time of the White House fire retrofit called “Phoenix” which we all thought was because of the 3600 III White House fire as rising from the ashes! The thing that scared me more than the newly added fire extinguisher was the possibility of the LS35 Switch contacts were extremely close to the metal B-transport which could easily short and burn out the whole wiring harness which was an immediate L4L and… Read more »

My third job at Wilde Sapte & Co in 18 Old Broad Street London 1975 to 1977 had a Blue 3600. I don’t recall a sorter on it.. Key Operator Training was done in house.

You should have worked on the 3600 III and the built in fire extinguisher. They say back in the day it was pushed out of the white house because of the fire…OH BOY>>>>

I liked working on the 3600-III. There was no fuser oil mess

so the 3600-III vacuumed up easily. The prints were good also, with a slightly embossed look.

The 3600 was the workhorse copier in the 70s which used a lot of energy to run but was far more efficient (and accurate) than a typing pool. They would catch fire very occasionally, I had one do just that in London. The fire could start in or near the brush housing due to a combination of fine toner (dust) particles and the corona static charge. Provided the doors were kept closed the fire would usually extinguish itself making a lot of smoke in the process which might set off smoke alarms and sprinklers. Oh yes, those were the days.

oh yes, the old “toner explosions” were quite a treat! A loud WHOOOOMPH, and start looking for PM kit to replace stuff. We found poor vacuum would cause that. there was a seal between brush housing and frame with an angled side would tear up due to main drive chain bounce. Dirt everywhere. But if you did right angle cam, adjust cam switches and fuser contact arc etc etc, this machine just pumped em out…

I find that a bit strange. I was serving about 100 Machines of different models. Many of them were 3600 (or 7000 which was the same machine with different optics). None of them ever catched fire…

3600III had a radiant fuser and a potential for fire hence the co2 bottle. 24/36/7000 had heat and pressure fusing with no fire hazard.

I was a service engineer on this and other Xerox products in the 1970s, This was an interesting product as you needed to be well trained to get the best out of it, but things could be done to tweek it to suit the customer. Unlike later models that were electronic boxes.