Xerox 9500

Last modified: Dec 13, 2024 @ 1:19 pm

October 1979: The Xerox 9500 duplicating system offered automatic document feeding and collating, reduction and double-sided copies, with the speed of two copies in a second. First copy after only 8 seconds.

The 9500 could be delivered with either a 24-bin or 50-bin sorter.

Did you know? The design name of the Xerox 9500 was Paragon

| SPECIFICATIONS | |

|---|---|

| Copy speed (per minute) | 120. First copy after 8 seconds. |

| Paper tray | Main tray: 2500 sheets Auxiliary tray: 550 sheets |

| Output tray capacity | 350 sheets |

| Finisher/sorter |  |

| Staple function |  |

| Reduction/zoom | 96%, 74%, and 65% reduction. Variable Reduction (Optional) Reduction Range-61 ,5% through 102% of original size. |

| Document handler | Automatic document handler with 200 sheets capacity |

| Dimension and weight | |

| Overall length (with 50-bin sorter) | 350 (cm) / 138 (inches) |

| Width | 182 (cm) / 72 (inches) |

| Height | 148 (cm) / 58 (inches) |

| Weight | 1348 (K grams) / 2927 (Lbs) |

| Floor space requirements | 4 x 3 (meters) / 15 x 9 (feet) |

Do you have any more information about this model, or have brochures / pictures? Please leave a reply in the form below, or send an email to xeroxnostalgia@outlook.com

My family bought the first 92 and 9500 series machines in Utah.

I grew up trouble shooting and running these machines. My dad was considered an SME on the 9500 series.

These machines were both maddening and amazing.

So much of my youth is tied to these machines.

I worked my way through college and law school in Boston at a copy shop that ran these machines. It was a great job, and the technicians taught me how to maintain it like a pro. I bet I could still slide out the belt and clean it, clear the document feeder, and keep the sorters running by stacking output on the top and bottom shelves so the baby didn’t have to stop running

The City of Los Angeles had 3 9500’s in their central duplicating room. I helped install them and I was the area rep for a number of years. One day I was in there working on one of them when one of the operators came up to me and said that every morning when they came in her machine would jam for 10 minutes and then be fine for the rest of the day. I looked at the log book and all the maintenance was up to date so I told her that I would come in when they opened… Read more »

I was a HVME—(High-Volume Marketing Executive)for Xerox in 1981 and my last day at Xerox (I went back to grad school) I brought in a SALES contract for a 9500 bought by IBM—this happened in Charlotte, NC and it was the first such sale to IBM in the country—as you may know, they and Kodak were our biggest competitors at the high end. Dallas

I do believe that Xerox used a mouse for a on screen program feature for their industrial 9500 copiers in the late 70’s and early 80’s. Too many staff were making mistakes with the 10 key programming and the mouse along with a screen display were added to these copiers so staff could review what they were programming into the 9500 before they started the run to reduce paper waste. I know this because I worked for Xerox in the mid 80’s. Steve Jobs saw this application at the Xerox research lab in Palo Alto and incorporated the GUI interface… Read more »

No mice on the 9200, 9400 or 9500.

There were no mice on the 9500. I was a operator on both 9400 and 9500, and there’s no mice on them.

Ran one of these in Hollywood back in the day, copying scripts etc. If you were good at running it, you could keep on printing while reloading the main tray, it was high tech for it’s time and yes the repair team from Xerox was top notch.

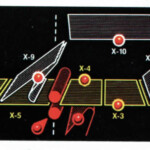

Oh, this beastie. I ran a 50-slot version as late as 1992, when I was told it was one of two still operating in the region. I can’t look at it without thinking of Nine To Five…or of lifting the panel when it jammed and seeing all those red lights.

Same, one of the last in ’92 here as well, except on the 9210. I owned that machine and still miss it today.

Fascinating, thanks. I operated one of these for a couple of years in the early 1980’s as an after school job. The machine struck me as remarkably high-tech for the time but the maintenance required to keep it operating and stay on schedule was crazy. Little rollers that started out nice and rubbery but quickly got hard and slick, the corotrons that always needed cleaning, and that damn belt which needed a weekly polish with chemicals that I’m fairly certain are banned now. But, I learned a lot and became rather self-reliant and a good problem solver / improviser. Having… Read more »

The pumice (photoreceptor polish) was safe, basically a fine grit in a liquid base to polish the surface of the belt. Film Remover was nothing more than 100% Isopropanol. The nasty stuff was the 6200 drum cleaner. You needed gloves for that. It was dumbed down later on… you can tell the old an new versions apart because one was in metal cans, one in plastic bottles.

Once Webster figured out how to get us field techs to keep all the transports to stay in alignment, I daresay that the 9500 was likely the best designed and overall the best performing piece of office equipment in the last 25 years of the 20th century. And that includes the much balleyhooed “Ten Series”. IMHO nobody has since come close to either the design of the machine, the robust build or the service and logistics organization that supported it – and after its heyday, Xerox began its long slide into irrelevance. A pitiful shame, but at least they managed… Read more »

I worked on the 9000 product band for years while working at Xerox as a Senior Tech. It seemed to me that Xerox wrote the Documentation and then made the M/C fit the Documentation very easy to trouble shoot especially after working on 914s and 813s. I however didn’t like changing the Xero shaft or silent chain, C15 and D29 problems could a hassel too.

But a lovely M/C too work on if Pm’d properly.

As a tech with Xerox 1985 to 2000 my 2 favourite machines to work on were the 9500 and the 5100. The 9400 weren’t bad and the 9600 was just problematic.

The 5100 was the first high speed modular photocopier and very easy to work on.

I used to operate a 9500 copier from 1981 -1990. It really was a copier ahead of its time. The work rate was unbelievable. It was a workhorse.

It surely was, and the 9700 that was developed from it gave me the leg up that any career can use. I was dispatched by Roland Magnin (RX MD at the time) to analyse a problem on what was the largest single account of these machines at the time in an operation called Datev in Nuremberg Germany. Went there with Graham Hoeness, encountered the ever memorable Fritz Bellinger, determined what the problem was and we got it sorted within the week, joy all around. Then later someone discovered that this lowly technician without any customer relations training had been let… Read more »