Xerox 914

Last modified: Dec 13, 2024 @ 1:21 pm

Last modified: Dec 13, 2024 @ 1:21 pm

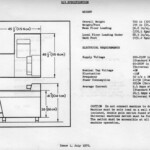

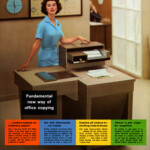

The Xerox 914 was the first automatic office copier in the world, and the production of the machine started in September 1959 by Haloid Xerox. This was a floor model which could produce seven copies a minute. The machine was the result of Chester F. Carlson's work in the xerographic process. 914 was one of the most successful Xerox products ever, a 914 model could make 100,000 copies per month. The weight of the machine was 648 pounds and measures 42" high x 46" wide x 45" deep.

Haloid Xerox named the 914 because it could copy originals up to 9 inches by 14 inches (229 mm × 356 mm).

The 914 tend to catch fire because of overheating. Because of this problem, Haloid Xerox provided a "scorch eliminator", which was actually a small fire extinguisher, along with the copier.

This is the first commercial of the 914 https://www.youtube.com/watch?v=9xZYcWsh8t0

| SPECIFICATIONS | |

|---|---|

| Copy speed (per minute) | 7 |

| Paper tray | n/a |

| Output tray capacity | n/a |

| Finisher/sorter |  |

| Staple function |  |

| Reduction/zoom |  |

| Document handler |  |

| Dimension and weight | |

| Depth | 115.6 (cm) / 45.5 (inches) |

| Width | 115.6 (cm) / 45.5 (inches) |

| Height | 104.1 (cm) / 41 (inches) |

| Weight | 327 (K grams) / 720 (Lbs) |

| Floor space requirements | n/a |

If you have more information about this model, or have brochures / pictures, please leave a reply in the form below, or send an email to xeroxnostalgia@outlook.com

[…] Opens in a new window xeroxnostalgia.com […]

I’ve joined the Xerox People FB group and spent most of the day writing notes about my time spent working at the UK National Workshops. Lots of reminiscences about early machines such as the 1860 and Copyflo.

I used to spend quite a lot of time at Mitcheldean when I worked as the UK National Workshops Planning Engineer in the late 60s and early 70s. A story I heard was that when the engineers there saw their first 914, supplied by Xerox, they started laughing as it appeared to be such a crude design.

Does anyone have one of the Xerox 914 fire extinguisher for sale ?

I had Steve Allen’s office (Meadowland Publishing) in Sherman Oaks, California in the very early 1970s.

I had to change a Puffer Solenoid on the 914 and was laying on my side with both hands inside of the machine. I felt the machine move a bit and shortly afterward saw Mr. Steve Allen upside down with his glasses hanging off from his eyebrows. He then said, “What’s the matter your fern broke?”

It took me a while before I was able to complete the task at hand, but they were a fun customer to visit.

I still have my Cat5 key from when I first learned to be a Tech Rep on the 914 and 813 in 1971.

I went to college 1968-1973 and libraries were one of the few places that had copiers and normally charged .10 a copy, which was expensive, given the low salaries of the day. I went on to become a ‘mailboy’ with Plantation Pipeline company in Atlanta that got in a 914 in ’68. I’d been taught to run a mimeograph machine and the firm had an offset printing press, but the Xerox machine was going to make a BIG difference…..legal secretaries had to type ‘perfect’ contracts with no errors and use carbon paper to make 5 copies using ‘onion'(super-thin) paper. I… Read more »

Mark, I have read a number of ‘confessions’ above and its great to hear all the stories. I just replied to Don above, and will make my reply short. I had the experience (as a copy boy) of stirring a pulverized coal slot in the front of the machine, and put out frequent little fires because of paper jams.. the principal I guess was to burn a magnetized ‘coal image’ of the original into the surface of the paper. I’m not kidding, I had a sack of pulverized coal next to the machine. Sounds crazy I know, but the office… Read more »

Rented only to start with, then subsequently sold (ORS) these lovely clunkers in Sydney, Australia after I joined Xerox in 1976. Demos could be fraught with risk with paper jams!

Left in 1997, so saw the whole transistion to digital, Star, WP, colour and high speed.

Great times and fond memories!

My first job at Howard Kennedy and Rossi in Cavendish Sq Lonodn 1972 to 1974 had a 720 in 1972. Burning smell if you opened the doors too fast after a fuser jam A massive clunking machine. I went to Euston Rd Xerox for Key Operator Training. Watching the Xerox engineers work here and at other offices I worked at, inspired me to take my C & G in Electronics and also become an engineer from 1980 to 1995 on Toshiba copiers

I started with Xerox in 1973, Akron, Ohio, as the BIC (Branch Inventory Coordinator), working in the branch refurbishing center. Our breakfast usually consisted of toast made on the 914 fuser.

Hi George. I see you still have your sense of humor. Hope all is well. Regards, Roy Roberts Kingman, AZ

Hey Roy !!

I stumbled on this website and saw the quick messages from you and George. Just to let you know I lasted 32 years at my FSM job until I retired in 2017. Those were some great times back in the 70s and 80s in Akron. Hope you are still healthy and doing well.

Tom Schuster – from NC??

Yes Tripp Akron is where my 42 year journey began. That’s where I started my 32 year FSM job. Are you still Xeroxing???

Hi Tom. It’s Jorge Martinez. I was watching a history of inventions show and they were talking about Chester Carlson. It made me want to look at some old photos of Xerox 10 series machines and older. I hope you’re enjoying retirement. I don’t know if I will ever find this site again. I stay pretty busy. But I just wanted to say, for the short time I worked for you, you were all right. Take care Sir.

tecnico xerox dal 1975 al 2016 41 anni e 3 mesi assistito 914,422, ecc ecc ecc un saluto a tutti Brizzi Massimiliano Italy

The 914 – 1000 series machines used a puff of air ( a solenoid and diaphragm coupled to a manifold) to blow the lead edge of the paper off the drum after image transfer. If this did not happen a photocell; called a “misspuff detector” would stop the machine; an all too common occurrence. At company social events wives were heard to ask “Who is this “Miss Puff”my husband is ALWAYS talking about.

I worked on a large number of Xerox products including the 914 and it’s derivatives, 813, 660, 2400, 3600, 3600 III, and 7000. Also Copyflo 24inch & 11 inch, and 1824 engineering print products, also an automatic-feed engineering print machine a lot like a larger 914 – the name escapes me just now. I was one of the very few Techs trained on the Xerox 3-2-1 and 1-2-3 products line which died a-borning, I also worked on 4000 copiers. Later I switched to the newly-formed Printing Systems division, working on the 1200 computer printer and the CFP ‘Computer Forms Printer’… Read more »

My first job at Haloid Xerox was in the New Products Evaluation Group testing the 914 engineering models prior to its introduction. One of my assignments was to service the first placement outside of a lab. The installation was at the Haloid Street facility. By that assignment, I was the first tech rep on a 914.

Hi Joe

I went to the first 914 official training class in Rochester. Nov1960. Stayed at the Manger Hotel.class taught by Merl and Roy. Were you in that class?

Tom Morris from the original Boston Branch.

In addition to the Haloid Street installation, I was the lead service technician on the Rochester Field tests at Bausch and Lomb , RG and E , Rochester Telephone , and the U of R. Most of the service techniques that we developed in the field tests were the foundations for the Training Merle Hydahl, Roy Takasawa and John Hyashi used for the service training curriculum and service manuals.

Hi Joe

Yes remember them well.

Those were the great days of Xerox

Joe, I had a like new 914 service manual that I donated/loaned to the Xerox Museum in Webster a few years ago. Ray there told me they had a 914 they were trying to get running. The Service Manual was to be a big help for them. I also gave them a like new 1000 radiant fuser, that might have worked for them on the 914. It was like new. I also gave them a like new 813 Service Manual. I never worked in the field, just Field Engineering (under Bill Draw/Len Schmidt) on 6500…. which had a paper path… Read more »

914s did not catch fire “due to overheating”, they caught fire when paper stopped under the fuser (which melted the toner, fixing the image). If paper paused under the fuser which had red-hot wires for heat, the paper burned.

That’s right. If the teeth on the rubber belt which drove the paper under the fuser wore off, the “horizontal transport” would hesitate, resulting in the paper stopping under the fuser and catching alight. I was privileged in South Africa to be trained on almost all Xerox products from the 914 up to the 9700 laser printer. Great days.

Good afternoon. I have been trawling the internet for years trying to find information from the earlier days of RX history and today I landed on this website. Soopa! Started in circa 1965, as an apprentice technician, at Park Royal. Training facility moving to Uxbridge ( first Xerox dept there ). Year 2 saw 813 & 914 family training which then led to 2400/3600. Back to Manchester year 3. Initially a walking eng. city centre and then on to a minivan and an area. Quickly left 813/914 and specialised on 3600’s ( all 2400’s had been converted by 69 ).… Read more »

I’m happy to know that you found this web site, and it’s great to hear your story of earlier days in Rank Xerox.

Hopefully this site will have even more info and pictures in the future. If you have any pictures of old Xerox machines, I’m always interested in such material. The email address to send it to is xeroxnostalgia@outlook.com

I can help with that 3600 circuit diagram .. if it’s not too late !!

https://memoriesofrxmp.info/

One of my duties with the 7th Admin Co, 7th Infantry Div in Korea in 1965-66 was to be the “Key Operator” for our new Fuji Xerox 914. (Partnership between Fuji and Xerox supplied Asia) The US Army had six 914’s in all of South Korea in 1965. Service was provided by one Fuji Xerox Tech Rep living in Seoul which required a two hour bus trip to our post at Camp Casey. Therefore, he taught me some of the simple basic repairs. In 1976, long after my military service, I was hired as a Tech Rep for Xerox Corp… Read more »

The 914 did not catch fire due to overheating.

The paper caught fire if it got jammed under the fuser. Generally if you didn’t open up the machine it just smoldered. The little fire extinguisher was only included with the original machines and most were removed in the late 60’s.

The 660 caught fire gor the same reason. A ‘fire wire’ was in place, it would melt to close the doors theory, no oxygen to burn….

Don, just curious to hear your reaction. I was hired as a ‘copy boy’ for the summer of 1967 at an American company in Stockholm. Numerous machines, but the crown jewel in the corner was the Xerox ..I think 914 model. Been so long I don’t ever remember exactly. What I do remember is that every morning I had to stir the pulverized coal slot in front, and always be aware when I copied because this machine often jammed and the paper caught fire. The extinguisher was a must at all times. I guess it operated on the principle of… Read more »

This was the first machine I was trained on in 1971. We then transitioned to the 720, and later retrofitted the 720 to a 1000. The name 914 indicates 9 X 14 paper, 720 and 1000 indicates copies per hour. Today we print at 180 prints per minute, or over 10,000 per hour, and we don’t call them copies anymore, but prints, because they are processed digitally and laser imaged.

We called the 914 “dial a fire” due to its habit of burning copies in the oven fuser.

Hi Daryle (and anyone who might be able to help me). I am a Danish writer, and I am really excited about finding this website since I am currently writing a novel that is set in California i 1974. I would like one of the characters to work with repairing Xerox machines (driving out to customers to help them with any problems). Would that be realistic? Do you know of people that had that profession? And if yes, what would be the main problems people would have with their machines? Also, do you think it would be realistic that a… Read more »

No, not many people were skilled enough to fix the copier, that was one of its major flaws.