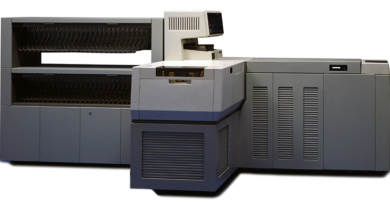

Xerox 9200

Last modified: Dec 13, 2024 @ 1:17 pm

April 1974: The Xerox 9200 duplicating system offered automatic document feeding and collating, reduction and double-sided copies, with the speed of two copies in a second.

Did you know? The design name of the Xerox 9200 was Ardrii

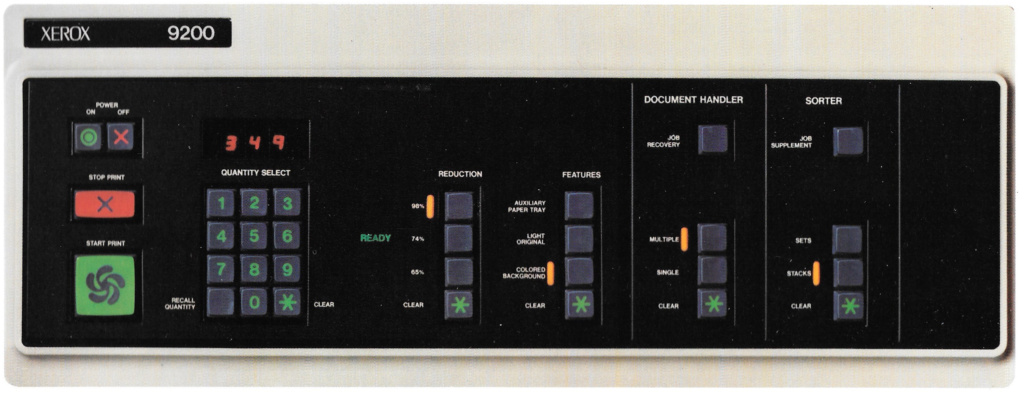

Xerox 9200 operating panel, and descriptions of the different functions.

Reduction: there where three preset reductions one could choose from - 98%, 74% and 65%

Fatures

Auxiliary paper tray - this was used for enabling the 500 sheet paper tray. An example of this could be when the machine was producing a large single sided series with copies, and the main paper tray was almost empty. You could then load the auxiliary paper tray with paper, push the button "AUXILIARY PAPER TRAY". The machine then started to feed paper from the aux paper tray, and you could then load paper in the main paper tray. By doing this, there was no stop in the production.

Light original -

Colored background -

Document handler

Job recovery - this was used to recover a job after paper/document crash

Multiple -

Single -

Sorter

Job supplement - if someone needed a few copies, and the machine was in the middle of a large series, you could put the job on hold and let others make a few copies.

Sets - for sort and make sets of a document containing several pages, one could enable this function.

Stacks - lets say you should make 3000 copies of one single side. Instead of have the copies come out of the main output tray (which could hold up to 250 sheets), you could stack the copies in the sorter.

| THE XEROGRAPHIC PROCESS IN THE 9200 |

The automatic document handler (1) holds up to fifty documents for automatic feeding and scanning. Alternatively, single originals can be placed on the flat glass platen (2). After exposure to the four flash tubes (3), the image is directed onto the xerographic belt (4), via the zoom lens (5), which can adjust the image size from 61.5% to up to 102% of the original size. The xerographic image is transferred to the paper, which has been fed along the straight paper path (6) from either the main paper tray (7) or the auxiliary tray (8). The image is fused (9) permanently to the paper and the finished prints then collect either in the receiving tray (10) or are automatically collated into sets or stacks by the 'limitless' on-line sorter (11).

| IMAGES |

| SPECIFICATIONS | |

|---|---|

| Copy speed (per minute) | 120. First copy after 8 seconds. |

| Paper tray | Main tray: 2500 sheets Top tray: 400 sheets |

| Output tray capacity | 500 sheets |

| Finisher/sorter |  |

| Staple function |  |

| Reduction/zoom | 98%, 74% or 65% reduction |

| Document handler | Automatic document handler with 50 sheets capacity |

| Dimension and weight | |

| Overall length | 350 (cm) / 138 (inches) |

| Width | 147 (cm) / 58 (inches) |

| Height | 144 (cm) / 57 (inches) |

| Weight | 1115 (K grams) / 2460 (Lbs) |

| Floor space requirements | 3 x 3 (meters) / 11 x 8 (feet) |

Do you have any more information about this model, or have brochures / pictures? Please leave a reply in the form below, or send an email to xeroxnostalgia@outlook.com

Anyone know whether the photoreceptor belt in the 9000 family duplicators was charged positive or negative, and roughly what charge voltage was used?

Thanks

I was a xerox engineer in the London area. I worked on high volume, so 9200 and the later versions up to 9700 etc . I would love to locate a 9200 service manual . Can anyone advise or know of where I could source one .

I was a 9200 sales rep in the mid 70’s in Lansing MI.

i finished number 1 in the Mid West Region reporting to Dan Light and Branxh Manager Bud Anjelus .

I really learned how to sell value .

I learnt the Xerox 9200 in high school. I was the Key Operator.

I was trained to operate the 9200 in Bloomington IL at Funk Seed International. I loved watching the papers collateral. That was 1976/77.

I was trained on 9200 in 1974 in Rochester NY. Chicago was where the field testing was going on. I had two engineering machines that were hand built and early models in my area. Every part replaced was packaged and sent back to Rochester for inspection along with paper work. Each call on E machines was taken by 2 Techs. One to do the work,the other to do the paper work. I remember putting an air conditioner in the sorter and cutting a hole in the input module to run the duct to cool the PRB Photo Receptor Belt to… Read more »

I was likely the last tech in the Los Angeles area to train on the 9200 about 1985 or so. By then the other 9000 series machines were out and it was a dieing product. But we still had a few of them out. It became a bit of a humorous situation in that by this time if you needed any rubber repair part you needed to order 2 or 3 of them to get one that was still good! Some of them had been sitting on the shelf at a parts center for close to a decade and were… Read more »

Great story, Robert! I can still see the rubber part that pulled the paper, especially from the manual feed tray on top. It was sort of like ribbed rubber. Worked great when it worked. Do you remember service tech Kelly? He was still servicing our 9210 up through at least 1992.

No I don’t remember a tech named Kelley but there were a lot of 9200 techs that had already moved on to other products and positions by the time I serviced the last few machines that were still out there.

l joined Xerox March 1968 in 1972 as a tech 5 became one of the first 9200

tech reps working for Bob Belmont

Xerox Nostalgia is a superb website with lots of excellent nostalgia from Xerox Corporation’s long line of famous products. I have many fond memories of using Xerox-branded copiers, including the 914, the 5400, the 2400, the 1065, the 1075, the 1090, the 5100, and various digital multifunction-type machines. But my favourite machine was the 9200. I really liked how its sorter worked, and how this arrangement minimized the handling of the originals by the feeder. I also really liked the 5090, which had a three-bin finisher that effectively cut the wear-and-tear on the recirculating document handler by one-third, compared to… Read more »

I loved, loved, loved working as a Tech Rep. Started off in dup school at Leesburg in 1975, went to “centralized” products in 1978, and absolutely had a ball. Made it to RES for the Rocky Mountain branch, and got to go to the ‘84 Olympics on Team Xerox. Favorite service call was the 9400 that kept losing its mind. Finally noticed the lead to the sorter’s anti-static bar was cracked when I got a 14000V shock one day. But that was the fix.

Paul,

I miss those days too. I own a Printshop in Cheyenne, WY now, but had to give up on Xerox products when 3rd party service came in. Those were the good old days.☺

Hmm. I worked with a Ken Hopkins in the Denver branch. You wouldn’t be?

The one and only.

In 1978 I was employed by The Royal Society for the Prevention of Accidents (RoSPA) as an offset litho printer, after about a year they decided that this process was too slow so the got in 9200 and had me trained to operate it. This increased my productivity greatly, unfortunately this meant that I had a lot of spare time when I was not actually working and was asked to change to part time hours, as I was already on a low wage I told them that this was not acceptable and was asked to leave them but before doing… Read more »

I’m only partially educated on the differences between 9200, 9210, 9400, 9500. My baby was the 9210, which I believe was the outer skin of a 9200 but with the upgraded copy quality of a 9500 (please correct if wrong or elaborate). Loved the control panel. Loved the aux tray with no lid that allowed for an easy drop of a full ream on the fly. Loved cleaning my own PR belt without need for a service call. Loved sitting on the little stool pulling sets for stapling – 3 at a time between the fingers. Loved the sound of… Read more »

Well, it’s official: I’m old! After hanging around the antique radio and phonograph forums and messing with stuff from before I was born, I find a similar “nostalgia” site featuring the machine I got trained on at the tender age of 20! While the TTL logic was fascinating, most of the work consisted of pumicing the belt, replacing rollers, and hoping those “B belts” would last another 100K. My favorite machine was the 9900, and I left Xerox just as the Docutech was about to become the next big thing.

I’m 65 now. I was told I was the most productive operator on the 9200 in the nation. Xerox hired me, and I was part of the 9200 team in Santa Clara California. The only competition we had was from Kodak.

Throwing my hat in the ring; My first job in this industry was as a 7700 as well as a VanDyk 4000 operator for the Vydec Co in Florham Pk, NJ. A year later we upgraded to the newly introduced 9200. I remember early on they had to bring in a tiger tech to deal with malfunctioning solenoids in the collator which instead of opening and closing in succession would just operate randomly causing all sorts of collation issues. A year later after moving it to a larger room we couldn’t figure out why there were large areas of deletion… Read more »

I joined Xerox in mid-1975 as an HVSE, selling the 9200 in Dallas. I loved the “Warm-up” film we had of H.G. MARSHALL,narrating a demo of the system, set to a Beethoven concerto. I’ve tried to find that video on YouTube or other internet sites, but no luck. Anyone know where I could find that?

I installed the 9200 for the E G Marshall demo. And stayed in studio everyday for two weeks to correct any problems. I met Mr Marshall, it was amazing to watch him come in cold and learn his lines and machine interaction. This was in Chicago in early 1974 when machine had code name Ardrii. Also helped install several machines in Sears Tower while it was still being built. I worked for Xerox for 31 years, started in 1968.

Didn’t you bail early and go back to Texas though ?

The 9200 was released around the 2nd quarter of 1975. I was the 6th person trained in the NYC Manhattan area. Leesburg was a new facilty, and it was running double shift to train up all the techs that were needed for the product.

I came on board with Xerox in 1976 iwith the 9200 in the Miami Branch. Best career choice ever! It was a great time and a great product. The training at Leesberg was second to none. I can remember just how massive it was and the sheer volume of paper it consumed, 7200 copies an hour. The main tray held 5 reams of paper and the aux tray about 250. The ADH (Automatic Document Handler) could be a bear to adjust, but when done to specification, it worked better than anything else on the market at that time. The photoreceptor… Read more »

This was the introduction into production copying/printing.

The 9200/9400 was, electronically, a fun machine to work on. It was a bear mechanically. It did, however, usher in the beginning of the end for the offset press. I was hired in Mid-Town Manhattan as a tech. I am still in production printing, albeit with Canon now, in the workflow software arena.

Thanks for the walk down memory lane!

Hired into “da loop” in Chicago Sept ’74 into Dups, 2400/3600/7000 as replacement for Senior techs going to the “it’s a miracle” machine. Being in Chicago Loop Brother Dominic made quite a few visits to major accounts and kickoffs. What a time it was and 43 yrs later we still consider it the best company back then because we were family. XICTMD is long gone, I think I spent @9 months there all together. Now it’s all plastic and sub assemblies.

Oh boy, the 9200. Hired as a tech rep in 1980, my first class was in Leesburg on the 9200. 6 weeks long. We were professional, coats and ties were the norm for daily wear at XICTMD. “You are the elite… If you are in this class, you are working on the most advanced Xerographic product ever invented. Our customers depend upon you for their service, and by proxy, their business and profit. When our customers are pleased with us, it is because you have listened to them, responded to their needs, and met their requirements. You will not find… Read more »

I began with the “Big Blue X” in 1978 on the 9200, as well. Training at XICTMD (Leesburg) was fantastic! Tech Rep on the 9200, 9400, 9500 and 8200. The Corotron wires were platinum (at least the charge corotron. The others were tungsten), when I worked on them. I wore a 3-piece suit, when I serviced the equipment. The vest kept my tie out of things. 😉

Do you remember the name and model # of the Xerox unit that was recalled for fear of counterfeiting our currency?

The 6500 color.

I ran one of these in 1985. It was a great copier. Loved the ADF, belt drum, and the sorter. Also had a service key to bypass the interlocks. No one would let that happen today. We called it E.T. ET only had one issue.. the fingers on the lower sorter started to rub on the belt rod.. about three months later, it had cut the rod and caused a big BANG!!!!.. This is how a machine should be made.

I was a Rank Xerox Work Controller (service engineer dispatcher) at Denham (near London) in 1976-77. Most of us were assigned to a geographic area, but we had one controller who was assigned to the 9200 across the whole region. Her job was to get a rep out to the machine within two hours of a call. Given the staffing the rest of us had to call on, and a problem (crisis?) we had with MTBF at that time, we struggled to get out to other models in two days.

I can’t thank you enough for posting my post. My mom will be glad to see this.

I worked in the concourse area of Xsquare. I was selected to be the “key operator” of the new secret machine being delivered. Armed guards, a secret room was constructed in Melvina Schmidts print shop, we had AB Dick duplicators. Xerox wanted to compare 9200 prints to the offset duplicator prints. 2-3 months in that room with 3 cameras, 2 3/4 in video tape recorders, and a note taker named Jan. She recorded every job, every jam. if I dropped something she noted “dexterity lapse-“. The design name of the Xerox 9200 was Ardrii, not Ardry, not Audry. It means… Read more »

Thanks for you correction about the design name of the 9200. I have now changed it to Ardrii.

You had some wonderful experiences in those early days. In ’79 I was running all sorts of machines including 9200s at an XRC facility in Mountainside, NJ. My first exposure to the Alto was in their front office and although we also had a 6500 the only thing they had was a slide projector adapter. That’s very cool that they had a laser scanner Frankenstein-ed to it but how did they generate color output? I do recall at least one guy was busted for trying to copy money. My final position when I left in ’97 was as a Docutech… Read more »

I just started my “career job” with Xerox as a new hire with the 9200 on Aug. 3, 1975. (Office: Los Angeles -Central) The 9200 had just lunched in the Western Region.

Day 2-Flight 76 LAX to Dulles Airport for 2-months of 9200 training at the newly opened Xerox training Center, Leesburg, VA.

The Xerox 9400, 9500, 8200 & 9700 laser printer were all products designed from the 9200 engine.

A very exciting company, and group of people I still call my friends. I will always appreciate the opportunities I enjoyed with my 20-career with Xerox Corp.

I had just joined Xerox and trained on the 9400 when the movie “9 to 5” was released. As soon as I saw it in the movie, I said to my wife, “that’s the 9400 I just trained on… but they’ve added a bunch of extra flashing lights to the UI” Of course, when the machine goes nuts I about died laughing!

We had one of these monsters at Bethlehem Steel Corp; Supply Division. Funny thing, they used one of these in the movie 9 to 5

Writing as an end-user rather than an engineer we found its document handler was fundamentally flawed in that it had to be loaded vertically from the front which meant the original was sent on a non-straight path and used to jam quite a bit on the bend, but what a machine when they worked, the 94/9500s were superb kit. I was sent on the “advanced customer training” (act) course, to Newport Pagnell, a two week residential to supplement the maintenance of them, probably the most enjoyable 2 weeks I ever spent with Xerox.

My first actual practical dive into the use of Boolean logic: flip up that card cage and install those jumper wires in the matrix to turn components on and off to troubleshoot wiring problems, dicey jam switches, and…and… wow, this was a fun machine! F_U_N _ !!! Except when you had to adjust the corotron currents, the BTR voltage, replace the flash tube trigger wires or the burned out flash tube end blocks in the optics cavity, replace the developer module roll rack chains and gears because the spray of developer from the lousy foam seals that acted like abrasive… Read more »

I know this is old, but you forgot the silent chain and fuser jackshaft! (And don’t get me started on “the last guy” who sprayed WD-40 into the sorter bearings so you got to clean up the mess.

Also, although the article above mentions a 1974 release, I could be wrong but I don’t remember the 9200 being generally available until later in the 70’s.

A late reply to this, but the 1974 release is taken from the Xerox fact book of 1987.

I was selling the 9200 (or not selling it, as the case might be) in 1975/76 and it had been out for a little while before. We were marketing it as a cleaner, less expensive alternative to the printing press; print shops and the craftsmen who were running the presses resented it.

The development of this machine – precursor to the 9400, 9500, 9900, and 8200 – was a truly massive effort buy Xerox, one of the largest and most expensive commercial projects ever undertaken. The field service force, of which I was a member, was at this time one of the most highly-developed logistical operations in American business.

The development and release of this machine also marked,, sadly, the final hurrah of the glory days. It was all downhill after this for many, many years.

I might disagree with you about that Jim, the way I see it, the Docutech series was brilliant.

I was involved in both product families. After the 9200, the big X was beginning its slide. The company was on a steep downward direction concurrent with the Docutech launch. We changed management from the Kearns era to the Allaire era which was a fatal error.

Yes from a management point of view I couldn’t agree with you more. I was just focusing on the tech itself. Personally, I stuck it out 18 years until ’97, a couple of years before the stock price plummeted, not because I had any kind of crystal ball, but things just didn’t feel right. Example: XBS had openings for Docutech analysts, which is what I was already doing for the general sales line. Service was downsizing and they (local business unit) already had someone else in mind and told me that if I wanted to cop for the job I’d… Read more »

When we launched the 9200 in 1972, all we had was analog machines, 2400,3600,914,813,etc. This and the 4000 series were the first digital machines with actual printed circuit boards controlling the functions. This was new to us in service, and we had to learn a new technology. The magnetic roll development, introduced on the 9200, is used today on most machines, and was a development of 3M company, licensed by Xerox.

Hi Daryle, You must have worked in NYC. I understand that was one of the first launch areas. (I started just after launch of the 9200 in the Western Region on the 9200 “New Hire Program”, 3rd. Quarter ’75) As you experienced, the 4000/4500 family first, then the 9200 were Xerox’s first digital “controlled” copier or duplicator. It was explained to me as a new hire that Xerox invested more money in R&D for the 9200, than Boeing spent for their newly introduced 747 jetliner. Xerox had fully gambled on the 9200 program. I remembered how pressmen hated the 9200,… Read more »

My dad had one of these in the general offices of the railroad where he worked. When he would take me in to work on weekends sometimes, I was always making copies of my hand, my face, etc., and he’d even let me copy things he received on his old Xerox Telecopier (I think they call those fax machines nowadays…) at the office that he had to distribute. I think that was responsible for my present-day office machine geekery.

yeah, it was always fun to make copies of hands or head. I remember that I did this myself 🙂 I have never used a 9200, but I was a operator of 9400 and 9500. Big machines that made a lot of noise.