Xerox 6500 color copier

Modified: December 13, 2024 1:26 pm by Admin

The Xerox copier 6500 color copier was introduced in May 1973, and made full color copies on plaine paper and transparents. 3M offered a color copier several years that required specially treated paper for each copy. The Xerox 6500 printed 4 copies in a minute, so it was rather slow. There are stories telling, that the 6500 also set copies on fire from time to time.

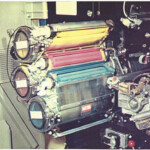

The process of creating color copies explained

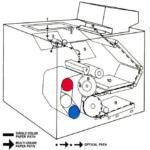

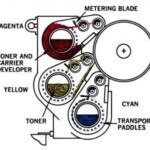

Document placed face down on the platen glass (1) is scanned by the moving lamps (2), and its image is projected onto the object mirror (3). The image is reflected from the object mirror through a lens and color-separation filter system (4) onto the image mirror (5). This mirror projects the image through the exposure box (7) onto a positively charged light-sensitiv drum (6). The light image, in the first cycle, has passed through a green filter and discharges the drum in non-image areas. Next, magenta toner, the filter's complementary color, is applied to the latent charged image remaining ont the drum with rollers containing rod magnets (8) -detail, above. Negatively charged toner, which coats magnetic-carrier particles, is taken to the roller by paddles. The toner is attracted to the charged image on the drum; carrier particles, which remain on the rollers, are recovered.

Paper from the tray (9) is held on a charged transfer roll, which attracts the toner image from the alloy drum and holds it on the paper. The paper is held on the transfer roll for up to three sequential images, depending on the number of colors selected. The second cycle exposes the document through a blue filter, applying yellow toner in exact registration over the magenta toner. The final cycle uses a red fiter and applies cyan toner over the magenta and yellow. The paper is the transported to the fuser (10) where heat fuses the color toners to the paper. The melted toners give a glossy appearance to the copy. The copy paper the goes to the receiving tray (11). The 6500 runs in full-color, three-color, or single-color mode. Source: Popular Science, October 1973

Thanks to F. Lee Johnson (former senior Manufacturing Engineer on the 6500 project) , for providing all the color print examples in the images section below.

| IMAGES |

| SPECIFICATIONS | |

|---|---|

| Copy speed (per minute) | 3.2 (full-color mode) 4.8 (three-color mode) 10 (single-color mode) |

| Paper tray | 500 sheets |

| Output tray capacity | n/a |

| Finisher/sorter |  |

| Staple function |  |

| Reduction/zoom |  |

| Document handler |  |

| Dimension and weight | |

| Depth | 117 (cm) / 46 (inches) |

| Width | 107 (cm) / 42 (inches) |

| Height | 117 (cm) / 46 (inches) |

| Weight | 472 (K grams) / 1041 (Lbs) |

| Floor space requirements | 3 x 3 (meters) / 9 x 10 (feet) |

Do you have any more information about this model, or have brochures / pictures? Please leave a reply in the form below, or send an email to xeroxnostalgia@outlook.com

I represented Rank Xerox Venray (Netherlands) from 1972 thru 1974 in the 6500 team in Webster. The intentention then was to build the European version in Venray. One of the tasks I had was to monitor the testing of the first 23 machines before shipping to Venray..

I was a 6500 Tech Rep in the Chicago Loop and then the suburbs, during the mid 1970’s. Installed sites included: Sears Tower- 35th Fl.; Chicago Tribune & Sun Times; Art Institute; legal offices and others. It was a fun job and I met a ton of interesting people. Had to take a call once for someone that was on vacation and drove to Naked City, Indiana, in the middle of winter and the drive was like two hours one-way. It was a nudist colony and everyone working there was butt-naked. The machine was located in a huge geodesic dome… Read more »

I think my grandfather(Kenneth Young) was on the team that helped build and design the 6500. I found this picture and a letter of authentication(which got lost over time) dated around 1970 in my mother’s photos soon after she died.

I once made a 65% reduced copy on a 6500. (Probably the first person to make a color reduction copy, but it requires a nearby 9400.) First, I took a color image, and scanned each color separately (the copier let you do that, with each color on a separate page). Then, I took those sheets to a 9400 and made a 65% reduction copy of each color. Then I marked the resulting black and white images by color (C,M,Y), and (you have to be quick here), slid each sheet on the glass in the correct order for each color scan.… Read more »

You would get a paper fire in the fuser and the post fuser paper transport belts areas if the paper stalled or curled up touching the fuses element causing the paper to catch on fire. Two monofilament fishing lines were located in that area. If one or both of them were exposed to heat or flame they would melt causing a circuit to be cut and shutdown would occur. A CSE would be required to replace them and check for damages to the fuser and/or the belts and replace and/or repair as needed. The Air Force had some of them… Read more »

I have an original Xerox color watch given to me upon completion of 6500 training at the leesburg facility

Awesome! I wish I could have a watch like that. Can you post a photo of that watch, I would love to see it. I started Xerox in 1976, June.

I have one of these watches as well!

Here is a picture of the watch

Here is a picture of the color copier watch.

Hi there, I have a question reg the Xerox 6500 copies, does anyone know what the size was of the platen glass where one need to put down the sheet to copy it? I really need to know this information. Thank you all very much for your support!

The 914 and the 720 were basically the same machine and the 6500 was based on the same chassis. I don’t have the documentation handy but I think the 6500 also made copies up to 9″ by 14″. That’s why it was called the 914.

Does anyone know if the dimensions listed for the height include the top smaller console or not?

In the 1980s, I had access to a Xerox 6500 color copier, which I used experimentally, for making art images. I also joined an art collective, known as The International Society for Copier Artists, which published annual editions of copy art, for subscribers from all over the world. This December, the Whitney Museum, in NYC, opened an exhibit, ‘Experiments in Electrostatics’, curated by Michelle Donnelly, and focusing on artworks made on a variety of copier machines; one of my images from 1986 is featured in this exhibit. I am stunned to have my art, from so long ago, displayed in… Read more »

Missed that! One Laurie Rae Chamberlain made a bit of a name as the “first” C/X fine artist in the UK. As mentioned above, I did a lot of punk badges using C/X, and the heat lamination worked really well with the toner to give an embossed effect, entirely unreproducible in this day and age. So collectors love’em. There was an exhibit at NYU in 2016. https://steinhardt.nyu.edu/80wse/projectspace/2016/12/imageasvirus

I was one of the first 4 engineers trained on the 6500 in South Africa. The last surviving one of six was in Durban Copicenter. I was responsible for its maintenance.

Hi Gerry, No doubt one of the ones you serviced was at letterstream in Shepherd Market. This was just about the only one I knew of in Central London and I used it to make punk badges which I sold at the Roundhouse I was very aware of the variations in quality, which usually showed up as greenish artifacting. However I used to have a lot of fun varying output by knob twiddling, shifting art between colour scans and other tricks. The badge prints were then heat laminated before being pressed at Universal Button in Bethnal Green. This gave a… Read more »

Hi Joly, As a matter of interest, it was my late mother, Gill Harwood, who ran Letterstream in Shepherds Market in the 70s. She had a printing press downstairs and did mention that she was one of the first companies to use this Xerox copier. She also told me that she had a couple of famous actors who used to photocopy their scripts on the Xerox, namely Diana Dors and Robert Vaughan! I’m intrigued that it was Gerry who serviced the Xerox…he must have known my Ma as you must have too. I do remember (as a 12 year old)… Read more »

The print manager was a crazy dude called Hugo. Very memorable fellow, bit of a mad scientist type.

I’m just seeing this but wanted to pop in. I worked at Letterstream for 3 or 4 years, leaving in early 1978. Edward Kalfayan owned Letterstream. I worked upstairs in word processing, often having to do overnight shifts to finish a job. I remember Roy who did the offset printing down in the basement, and I sure remember Hugo! He had a German last name that escapes me now. Wild hair! I was there when the 6500 arrived. It was a HUGE deal, as I think we were the 1st in London to have it. We all learned to operate… Read more »

Hi Jeannie! Wow! My ma left in ‘76 before we all moved down to Somerset; and coincidentally Eddies son Yelland was my sisters doctor down in Somerset! I used to do collation upstairs in the school holidays.

So glad you got my post! I wish I could remember your mom. I was most certainly there in 1976. Vicki Reid was the manager upstairs…they called the dept ‘automatic typing’ then. She and I were close friends and I went back for her wedding in 1980, after I had left Letterstream and come back to the States. If you were doing collating for us, I probably met you! lol. I still have my old business cards from Letterstream, among my souvenirs. Great to hear from you! Now I am on a mission to find Hugo. 🙂

I was the first U.K. Trained field engineer and looked after the initial small number of machines. The majority were installed in xerox copy shops and London branch offices. The initial colour set up was very time consuming and when the machine was left overnight the quality could have altered if the photoreceptor had been over exposed during set up.

The Bank of England were very concerned with the potential ease of producing counterfeit bank notes.

I worked in New York State north of NYC. We had several large corporate accounts that had multiple 6500s on site. Pepsi had 5 of them at one time. The quality was never that good on the 6500. Later models of color copiers/printers print a micro sized machine serial number using the yellow toner to identify the exact printer so it location could be found law enforcement.

I have a brochure for the 6500 that was created around 1972/73. I would be happy to scan/pdf or let me know how I could be helpful. I also have brochures for the 4000, and a few product sheets for 9400.

Sorry for the late reply. It would be really great if you could scan the brochure for 6500, 4000 and the 9400.

The email address is xeroxnostalgia@outlook.com

Thanks 🙂

In the late 70’s I worked at the Atlanta central refurb center rebuilding 6500’s and converting used “6200’s”, which only printed red blue and black to 6500’s. We converted the developer units to C,M,Y. There was no black developer unit in the 6500. The three primary colors made an “almost” black print. We rebuilt and reinstalled the filter lens mechanism, and rewired the machine. Many of the wire numbers had to be changed, but rather than replacing harnesses with wire numbers printed on the wires we all had drawers full of tiny numbered sleeves that we slid onto the wire… Read more »