Restoration of a Xerox 4000 copier

I have been looking for a Xerox 4000 copier for a long time, which I could play with. In February 2019, I was contacted by Xerox Venray in the Netherlands, and they had two Xerox 4000 copiers. They asked if I was interested in the machines, and of course I was.

On Monday March 18 2019, I received the two Xerox 4000 copiers. Since I had no other suitable place, they were put in my garage. It was winter outside and cold in the garage, so I thought I would wait until it was spring and better temperature outside before trying to start the machines. On Saturday, March 30, I could not wait any longer and started up one of the two Xerox 4000 copiers. After the machine had warmed up, I tried to make a copy, but as expected, no copy came out of the machine. There was obviously something wrong.

After a while I found out what the problem was - the machine could not feed paper from the main paper tray. I added paper in the aux tray and tried to make a copy, but the same thing happened there too… the feed rollers could not feed the paper further into the machine.

I thought maybe it had something to do with the electronics in the machine. Since I had a spare machine, I switched one circuit board at a time from the spare machine to the problem machine. After I had replaced all circuit boards, the problem was still the same and I gave up trying to get the machine repaired.

A retired Xerox technician contacted me

In early January 2020, I got in touch with a technician in the United States who had been a product specialist on Xerox 4000, and I told him that I had a "paper feed issue" with one machine. He had a buddy that he had worked with in Xerox before, and I posted some videos of the paper feeding issue. They saw that the feed clutch was activated at the wrong time. From the videos it looked like the feed clutch was being energized at the wrong time they said. I was told that a common problem was a black cam on the cycle control would crack and slip on the horizontal shaft causing it to be out of time. For the aux tray the feed clutch is energized when the cycle control switch S2 is actuated. For the main tray, the feed clutch is energized when S7 is actuated. They told me the cycle control assembly must be timed to the drives.

I am not a Xerox technician, but I have some technical and mechanical understanding. Now the job began to try to solve this "paper feeding issue".

I checked the S2 and S7 on the cam, but they were not loose in any way. Both technicians had seen more of the video, and they believed that there was a "timing issue" with the machine that led to the paper not being fed into the machine.

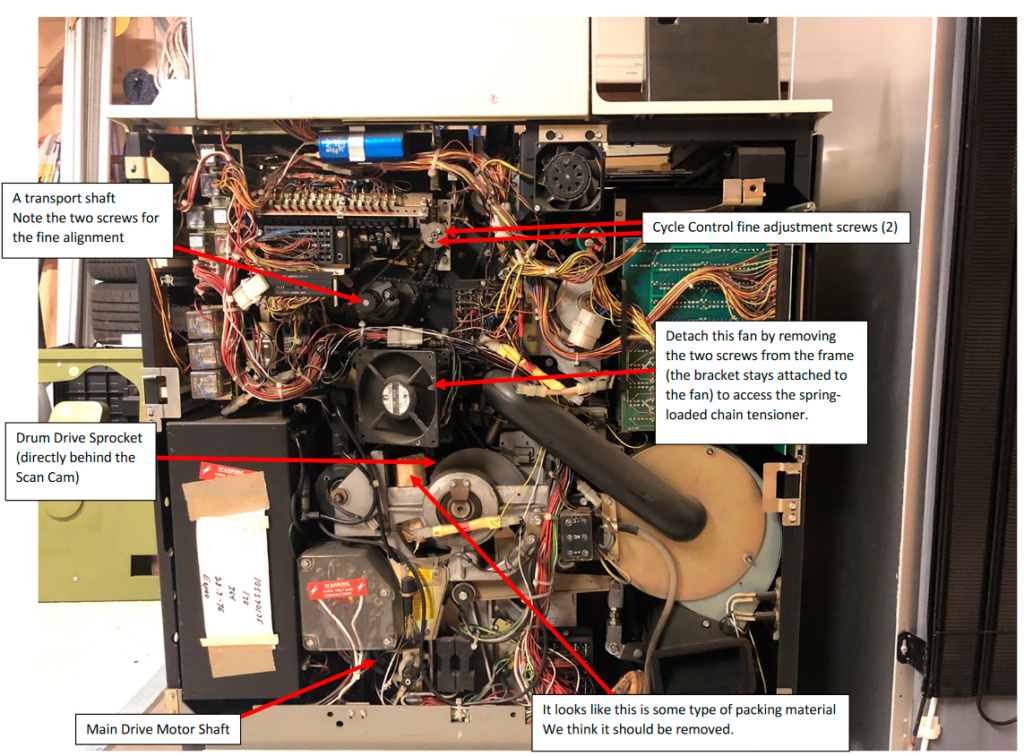

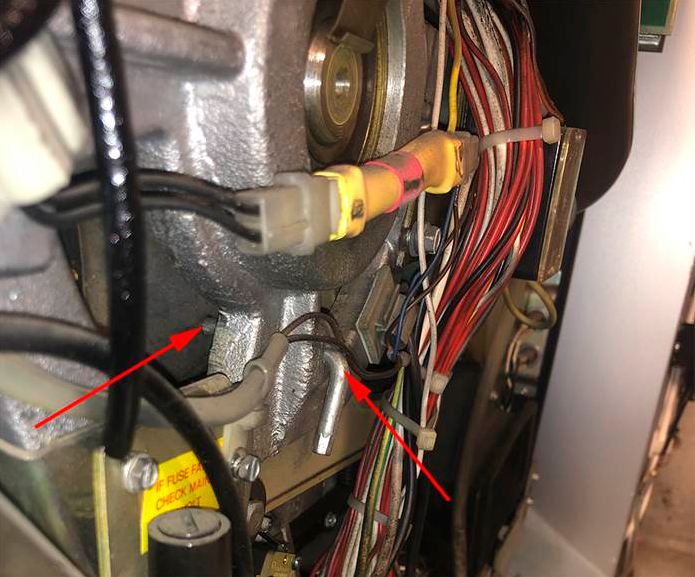

Here is a picture of the back of the machine and the Xerox technicians had explained several of the parts.

Here is a list of steps I needed to do:

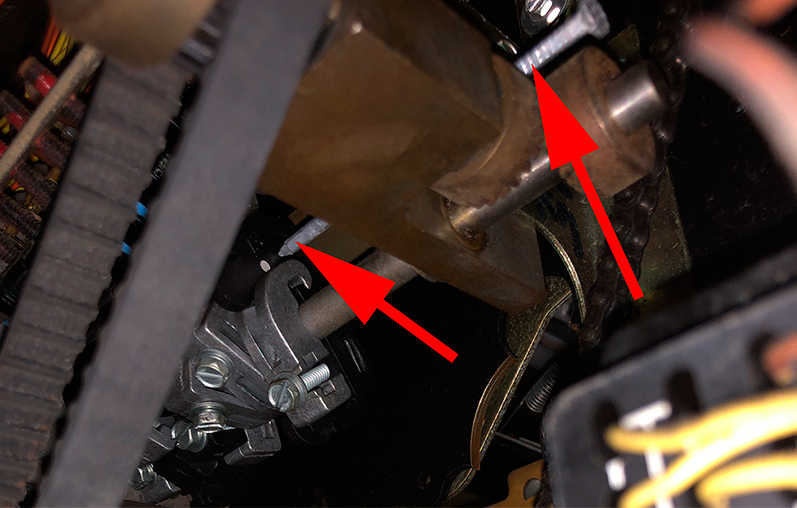

- Hand crank the main drive motor clockwise until the pin can be inserted into the scan cam

- In the front of the machine place the pin through the frame and into the disk of the A transport (this may require loosening and repositioning the drive chain in the back of the machine for the rough setting and reposition the hub to obtain perfect alignment)

- With the scan cam pinned, align the cycle control using a smaller pin from the right end (you may need to remove the drive belt to get the pin to slide into the hole of the cams)

- Reinstall the cycle control drive belt (you may need to loosen the two small screw on the hub of the pulley to get the correct alignment)

- Remove all the pins and power the machine up and see if it feeds paper (the copy will be mostly black but we can deal with that later)

Part of the problem was to find out where the different parts indicated in the picture were, and then it was also to understand the technical language that was in English. My native language is Norwegian, but I have had English at school. Yet with so many technical words in English, it got a little confusing at times.

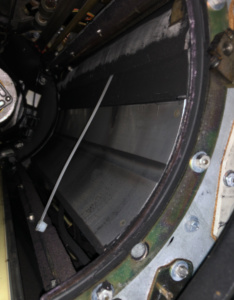

I managed to hand crank the machine, so that I could insert the stick into the scan cam as described in step 1.

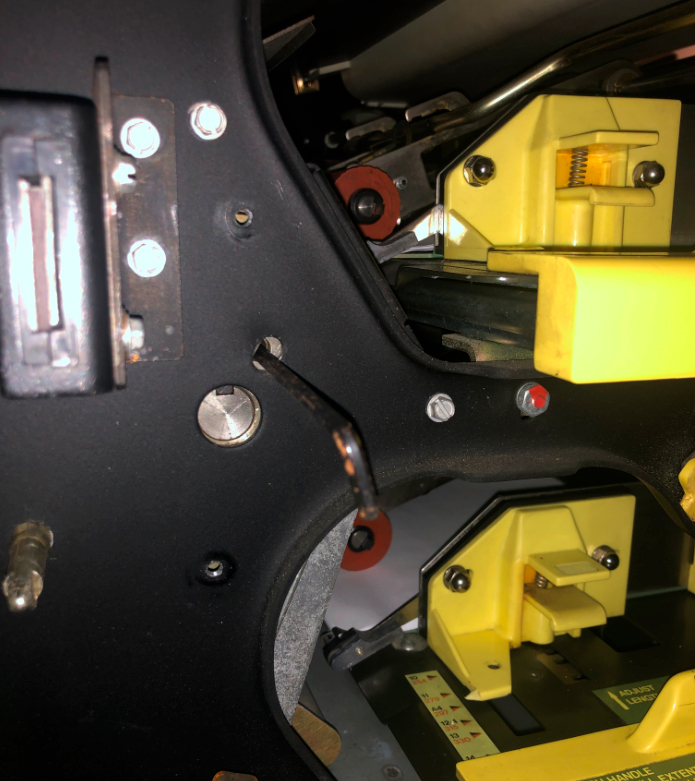

According to step 2, I should insert a pin into the disk of the A transport. See the picture below.

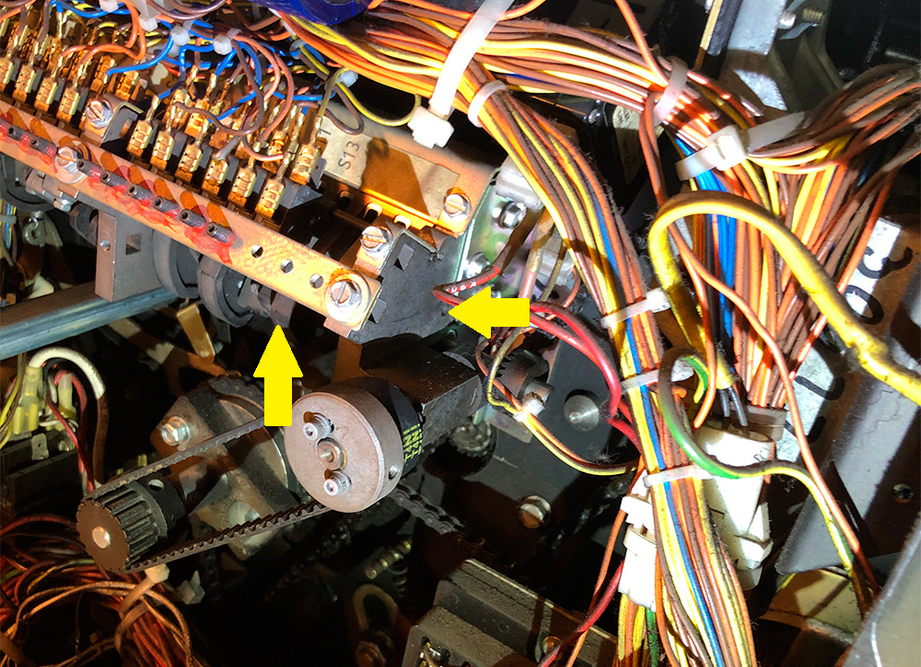

In step 3 I should “align the cycle control using a smaller pin from the right end (you may need to remove the drive belt to get the pin to slide into the hole of the cams)” When working on this step, I had problems to understand exactly what to do.

May 24th 2020 - breakthrough

Because of the Corona pandemic and some email issues, I have not had contact with the Xerox technicians for a while. It was now May and I started the work again to get the machine fixed. I was still stuck in step 3 and there were several emails back and forth, between me and the Xerox technicians because I needed more detailed explanations.

After a lot more detailed instructions, I managed to complete step 3, and performed step 4 and 5.

It was Sunday 24th May 2020, and I powered up the Xerox 4000 and was ready to make a copy and see if the paper went through the machine. When pushing the start print button, the machine cycled as normal when started copying after power up. I remembered that I sat on my knees and looked into the machine while it was running, and then it suddenly stopped. I thought there was the feeding issue again, but that’s not the problem… when I got up, I saw a copy in the output tray. Finally, a copy was successfully made!!!!

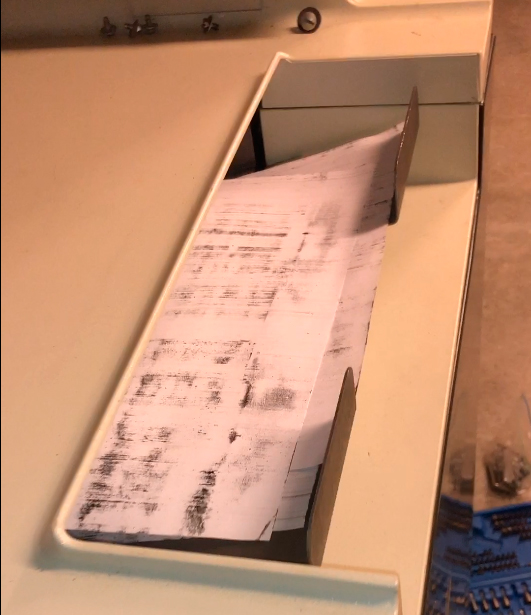

There was only a blank paper on the platen, but the copy that came out had a lot of streaks on it. There was obviously more that needed to be done. Below is a image of the first copy.

The next step was to clean the mirrors inside the machine. I had to remove the cover on the left side of the machine, but I could not do that since it was next to a refrigerator. I had to get a jack trolley to move the machine so that I could clean the mirrors. After a couple of weeks, I got hold of a jack trolley, and moved the machine so that I could clean the mirrors.

Adjusting copy quality

The doctor blade in the machine also had to be replaced, and I ordered it from Partsdrop.com. They did not have the correct blade, but they found one that fit anyway even though it was intended for another Xerox model. It took a little over a month before I received the doctor blade. When I received the blade it was installed. Now everything was in place… mirrors were made clean, and the machine had a new doctor blade. I was very eager to print a copy now.

Below you can see how the copy looked. There were areas where the text was washed out, and there were also some black dots there.

After sending over a picture of the copy to the Xerox technicians in the US, they thought that the areas that were washed out were caused by "developer chute blockage". A dirty or failed corotron wire could cause the black dots, or pepper tracks as they called it.

To fix the "developer chute blockage" problem, I was recommended to slip a plastic strips partway into the slot about ¾ of the way up the smooth curved face of the developer housing and slide it back and forth a few times.

I cleaned all the corotrons and hoped that the pepper tracks were gone. After this was done, I ran new copies that got much better.

Below is an image of copies produced by the Xerox 4000 copier after the adjustments.

I was very satisfied with the quality of the copies, and the mission was complete!

With a great deal of help by the two Xerox technicians, I finally had a Xerox copier that worked. I am forever grateful for all the help I got from the two technicians, and that they had patience with me when I had problems understanding the different instructions, they sent me.

| MISC IMAGES |

| MISC VIDEOS |

I joined Xerox in 1972, worked on Standard’s, 813’s, 914’s and 4000’s and then P.S. Retired after 41 years. I had the most fun working on the 4K’s. I just happened on to this site and just seeing the video of the machine running and you guys comments about “a” transport bearings and oil soaked cleaners put a smile on my face and made my day. Thanks, R245 PS: I can remember calling into dispatch and they would ask for my employee # I would give them R2D2 then I’d say how about CP30 🙂 May the force be with… Read more »

Joined rx Sydney 71 trained 4K at launch in72 took them from the cradle to the grave as district product specialist retired 2015 as stench on the Gold Coast dealership

Hey Guy, this is 445h, remember me?

I worked on everything and ended up servicing 6180s and networks.

This site is awesome as I can see myself spending a lot of time here.

Ron.

Hi Ron!! I sure do remember you. I was going through some old pictures not to long ago and theirs one of you at my apartment on the east side of Columbus. Drinking few beers after work. How have you been? Are you still around central Ohio?

I worked as Planning Engineer, UK National Workshops, for a few years in the 1960s. Manager was John Baker. While there I worked part-time for a Psychology degree at Birkbeck, University of London. When I got my degree I worked for a couple of years at Xerox Research (UK) in the Industrial Design/Human Factors dept. on human factors. Boss was Frank Zinni, on secondment from Xerox Corp. in the US.

1969-2005, Nothing like a clicking auger call with fuser oil on the floor for your last call of the day. I’d do it all again in a moments notice.

070B ? Employee number Ron ?

Carboni, still remember my ride along with you in the field and PSD.

A Transport?

been there, done that

You could always see who was a 4000 tech by looking for the tell-tale wear-marks at the tips of one of your shoes. You had to support the heavy side panels with your foot as yoi popped them on and off!

I joined Xerox in 1977 as a Tech. Rep. servicing the 4000/4500 copiers and assigned to the Headquarters Branch in Rochester. Eventually trained on all the med-volume products including 1075/1090, 5400, 5600, 5700 and Alto printers. Have to say the pictures in the above article show a pretty pristine machine. The only time I remember seeing them that clean is when they were new. I got quite proficient on the 4000/4500 and was once told by a Leesburg trainer that an experienced 4000 rep could fix anything.

Joined Xerox in 1973. Sales Left in 1977 to go with Compugraphic. Returned in 1978 with the Cheshire Division of Xerox. Back to Xerox C/D Division when Cheshire was sold in 1982. Joined Printing Systems in 1984. Became DocuTech Specialist in 1990. Left to create my own digital printing company in 1995. Returned to Xerox in 1998. Ended my Xerox career in 2006. I watched Xerox rise and sadly I saw it fall, but mine was a lifetime of experience that is beyond comparison. People and products that led the world for a period of time that made us all… Read more »

I was a new Sales Rep in St. Thomas Ontario Canada in 1976. One of my customers complained that their Xerox 4000 was always printing too lightly. I mentioned it to one very friendly technician who said that the exposure slots may have been set too small. He then proceeded to show me where they were stored on the machine and how to change them. A few things he did NOT mention; wasn’t in his his assigned territory, or that the wider the slot, the dirtier the machine would get, or that they were measured on copies between service calls.… Read more »

I hope you used a box of A4 Xerox paper as a stool when working on the machine 🙂

No, but I will use it next time👍

Brought back so many memories of the late 70’s, working on 4000’s every day for many years,drilling holes in the rear frame on every visit so making it easier to change the A transport drive pillars.what a fun time and gave the bad knees as a result !

I got a Xerox “Pride” award for designing the sticker for electrometer readings on the inside of the main door. It started by me just writing the corotron readings along with the electrometer readings on the inside of the door. Our regional Tech Spec, Mr. Larry Jones saw it and together we created the sticker for the inside of the door so other Tech Reps would be able to see what the settings were. This was in the Western Region of Los Angeles.

That name sure looks familiar. I worked on 4000s from my start at Xerox Century City in 1973 until they died out. Transferred to the San Fernando Valley branch in 1977. Left in 1991 to go back to school. It was a great run with great folks, though I might take issue with the east coast management. When I look at the back of a 4000 now I wonder how I ever worked on that thing!

Hi Ken,

I remember your name.

I was in 5730, San Fernando until 1978 when Larry Jones got me an interview in El Segundo to work on the development of the 5700 and 9700.

I brought Ted Hauk over with me and he ended up in Mid Volume Field Engineering. We still chat on the phone.

There are a bunch of us who worked in PSD over the years on a group called the Grunions DL. People from 1200, 5700, 8700, 9700, Manhattan (4135), and 4180 development.

I thought I remembered your name also, but at this age things get murky. Went back to school after I left, got an EE, ended up with HP/Agilent in Santa Rosa doing microwave test equipment stuff. Ended up in far Northern Cal away from all the hustle and bustle of the city. Few neighbors and wide open spaces. Good to see a few of the old gang are around and found this place. I’m a ham radio guy and found a trainer from City of Industry training center (I think that’s where it was) who was also a ham. Small… Read more »

I used to work in the Century City Branch in 1977 to 1981 on a 4000 CST. Worked most of the territories until I went to El Segundo PSD.

I started working with Xerox in 1979. 4 weeks at Leesburg Training Facility. Retired after 20 years, when copiers started becoming modulated. Enjoyed every year, learned a lot that applies, even in todays tech world.

Poor Quality – Need a current shoe to mic those corotron wires and developer housing electrodes – after a developer change – Ha Ha.

This was a great trip down memory lane!

Thank you for this article on the Xerox 4000 and entire site. Lots of fantastic information.

Hi Jim. My sister sent me this…asked if I miss it. She worked at O’Hare where I started. Best thing I learned from Xerox was how to consume vast amounts of alcohol.

It must have been all the parties we had Don.

Began my 35 year close relationship w/Xerox in 1972. Graduated in machinery with the 10 series, 50 series then Print Systems in 1990. My machines were MICR 9790’s and later 4180’s printing Xerox employee checks for all of US Marketing Group from Bldg. 300 Webster. Direct deposit killed that then market share dwindled. I retired well. My body did not. Hips, shoulders, heart…I’m a mess. But I had fun while it lasted. #X837

Hi Don, remember the CRT on the MICR 9790 that cost over $10,000? I was the Field Engineer on the MICR Box. We used to have a guy come by the lab in El Segundo to collect the “developer” and recover the silver from it. I also was responsible for the PCUI on the 9790. The best PCs that we had before we got ASTs were Pentium boxes manufactured in total by Intel in Arizona. We also worked on a version of the 4135 of the PCUI that was a circuit board that fit in the card-cage in the 4135… Read more »

$10G’s? Geesh…I played with them a bit but I would never guess they’re worth that. Anyway you must know Eric Mueller? I loved that guy…he rescued me a couple times on that 9790 frame and helped edumacate me on them. He was back and forth Segundo hotline and FE. I made a couple trips out there unrelated to PS. I launched the 1090 telephone interface to the internal district out there. I was on 4135MICR BEFORE 9790 training with a non-Eng speaking partner from Finland. That 9790 had quirks going backwards in technology for me. I enjoyed 3rd shift listening… Read more »

Don, you haven’t changed a bit! Hope all is well! Hi to Brad and Randy!

Hey Don! I made it 34.5 years before I left for another job. You always cracked me up. Enjoyed working with you, Craig, Bill H. and the rest of the folks at the Internal District.

Jimmy, was this the one that Mikey called me on?

It sure is. Great to see it working.